When embarking on a new construction or furniture project, one of the most important materials to consider is plywood. Whether you’re building cabinets, floors, or decorative walls, choosing the right type of the panel can make all the difference. Plywood is popular for its durability, cost-effectiveness, and versatility, but with so many varieties available, it’s crucial to pick the right one for your specific needs. In this guide, we’ll explore the key factors to help you make the best selection.

Understanding the Importance of Plywood

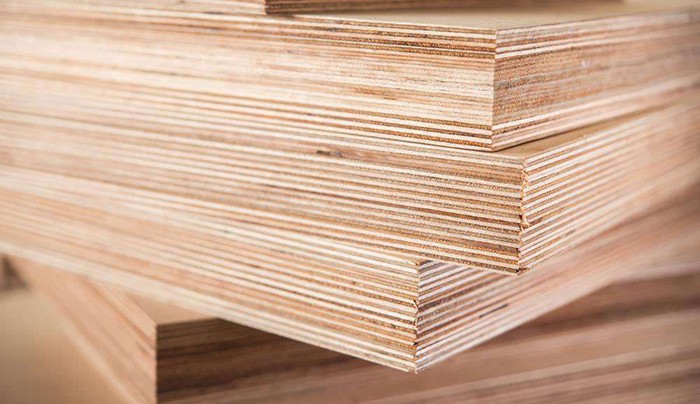

This panel is widely recognized for its durability, affordability, and ease of use. It is created by bonding thin layers of wood veneer together, with the grain of each layer oriented in a different direction. This cross-graining technique gives the panel its strength and prevents it from warping, cracking, or splitting over time.

Plywood’s versatility allows it to be used for various applications including:

- Home Furniture: Cabinets, beds, tables, and chairs.

- Construction: Partition walls, flooring, and ceilings.

- Interior Decoration: Decorative partitions and cabinet surfaces.

- Outdoor Applications: Doors and outdoor furniture.

1. Identify Your Project’s Needs

The first step in choosing the right plywood is identifying your project’s specific requirements. Understanding the type of structure or furniture you are building will help determine which plywood will work best. For example:

- Home Furniture like cabinets and tables require plywood with a smooth, aesthetic finish.

- Outdoor Applications demand water-resistant or marine-grade plywood to withstand moisture and temperature changes.

- Construction Projects may call for a thicker, high-strength plywood to support load-bearing structures.

Clearly defining your project’s purpose will narrow down the right type of plywood based on durability, moisture resistance, and overall aesthetics.

2. Explore the Different Types

Plywood comes in several different varieties, each suited to specific tasks. Here are some of the most common types you’ll encounter:

Softwood Plywood

Softwood plywood is the most affordable and commonly used variety. Typically made from redwood, pine, or cedar, it is often used in construction for sub-layers, roofing, and walls. Its affordability and strength make it ideal for building large structures or for use in areas that won’t be visible, like subflooring.

Hardwood Plywood

Hardwood plywood is made from denser woods like oak, maple, and mahogany, making it suitable for furniture production and decorative elements. This type is favored for projects requiring a sleek, polished appearance, such as cabinets, chairs, and shelves.

Water-Resistant Plywood

For outdoor furniture or any construction exposed to the elements, water-resistant plywood is your best bet. This type is specially designed to resist moisture and extreme weather conditions. It’s treated with waterproof glue and made from high-performance wood such as Douglas fir.

High-Strength Plywood

If your project demands a heavy-duty material, opt for high-strength plywood. This is typically made from high-quality wood like birch and is designed to withstand tough environments. It’s commonly used in construction projects like boat building or for high-end furniture that requires extra durability.

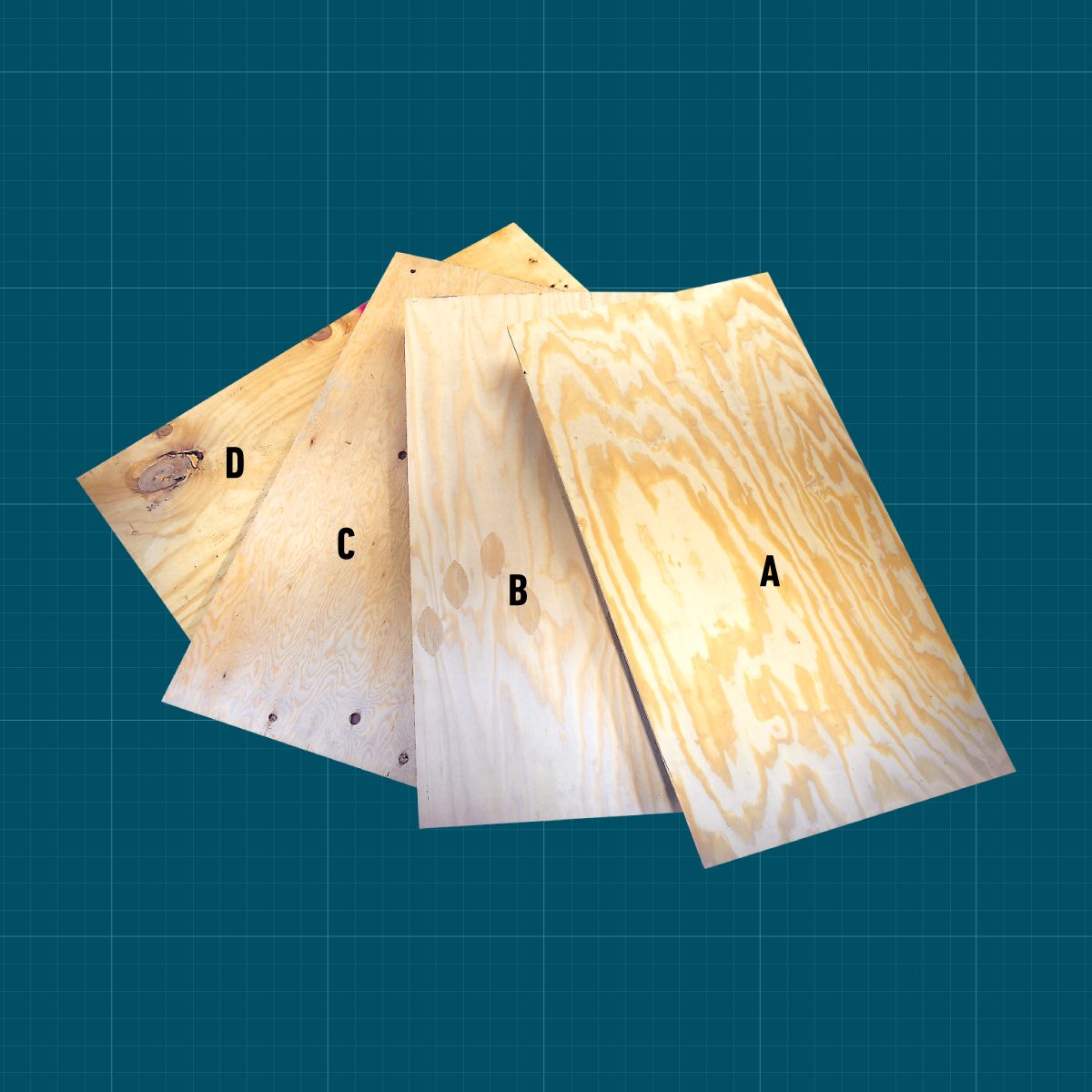

3. Consider Plywood Grades

The panel comes in various grades, which indicate the quality of its finish and construction. These grades typically range from A to D, with A being the highest quality and D being the lowest.

- Grade A is smooth and free of defects, making it ideal for projects where appearance is important.

- Grade B may have minor flaws but is still suitable for visible areas of furniture and cabinetry.

- Grade C and D are more affordable and typically used in construction where the panel will be covered or painted.

Understanding the grading system can help you choose the right selection that balances both quality and cost-effectiveness.

4. Check the Thickness

Typically ranging from 1/8 inch to 1 inch. The thickness you choose depends on the project at hand:

- Thinner panel (1/8 to 1/4 inch) is perfect for lightweight projects like decorative panels or cabinet backs.

- Medium thickness (1/2 to 3/4 inch) is ideal for furniture construction and partitions.

- Thicker (up to 1 inch) is used for heavy-duty construction projects or load-bearing applications like flooring and structural walls.

Always ensure that the plywood thickness matches the weight and pressure demands of your project.

5. Focus on Moisture Resistance

If your project is exposed to moisture—like outdoor furniture, bathroom cabinets, or kitchen surfaces—moisture resistance becomes a critical factor. Plywood designed for humid environments typically uses waterproof adhesives and has a special coating that prevents the wood from warping or rotting. Marine plywood is an excellent choice for such projects, as it’s highly resistant to water and humidity.

6. Evaluate the Veneer Surface

The veneer layer on plywood determines the appearance of the finished product. Some panel is made with high-quality natural wood veneers, while others use engineered wood that mimics the appearance of hardwood. If your project requires an attractive, finished look, opt for panel with a smooth, high-grade veneer.

For example, hardwood panel often has a polished veneer that’s perfect for high-end furniture, whereas softwood panel may have a rougher surface that works well for structural or sub-layer purposes.

7. Choose a Reputable Supplier

To ensure you’re getting high-quality panel, it’s essential to buy from a trusted supplier. Look for suppliers who provide clear product information, including the wood’s origin, quality certifications, and sustainability practices.

Consider the following when selecting a supplier:

- Product Quality: Make sure the panel meets international standards for durability and strength.

- Customer Service: Reputable suppliers offer excellent customer support and long-term warranties.

- Wood Origin: Choose material sourced from sustainable forests to contribute to environmental protection.

Conclusion

When it comes to choosing the best panel for your project, understanding your specific needs is key. From identifying the right type to considering moisture resistance, thickness, and veneer quality, each decision plays a critical role in the final outcome. By following these 7 essential tips, you’ll be well on your way to selecting the best selection for your next home improvement or construction project.

With the right selection, you can achieve a balance between durability, aesthetic appeal, and cost-effectiveness—ensuring your project stands the test of time.

You can read more articles by visiting our blog here.