Discover the amazing advantages of engineered wood and why it’s becoming a top choice for homeowners. Learn the 7 key reasons why engineered wood is a smart investment for your next project.

What is Engineered Wood?

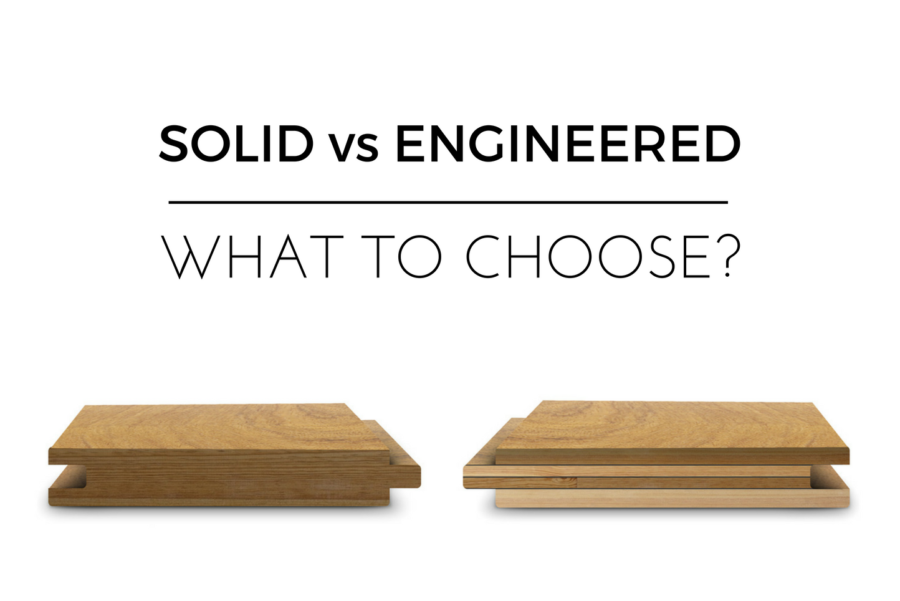

Engineered wood is a modern, versatile building material made from layers of wood fibers, strands, particles, or veneers bonded together with adhesives. Unlike solid wood, which is cut directly from a tree, engineered wood is created using various wood components that are engineered to create a strong, stable, and durable product. It’s quickly gaining popularity in the construction and furniture industries because of its reliability, affordability, and sustainability.

The production of this wood involves binding multiple layers of wood together using adhesives, heat, and pressure. This process results in a product that’s more dimensionally stable and less prone to warping or shrinking than solid wood. Depending on the type of engineered wood, different layers and wood components are used, making it suitable for various applications.

7 Reasons Why Engineered Wood is Better Than Solid Wood

Stability and Durability

One of the most significant advantages is its dimensional stability. It doesn’t expand or contract as much as solid wood when exposed to moisture or temperature changes. This makes it ideal for areas with fluctuating climates or high humidity, such as kitchens and basements.

Cost-Effectiveness

Engineered wood is typically more affordable than solid wood. The use of recycled wood fibers and less-expensive materials makes it a cost-effective option, especially for large projects.

Eco-Friendly and Sustainable

Engineered wood is an environmentally friendly choice since it uses wood more efficiently. By using smaller wood pieces and utilizing faster-growing tree species, it reduces the demand for slow-growing hardwoods, helping to preserve forests.

Versatility in Design

The structure allows for various applications. Whether you need flooring, cabinetry, wall panels, or furniture, engineered wood can be tailored to meet your design needs. It also comes in a wide range of finishes, textures, and colors, making it easy to find a style that suits your space.

Ease of Installation

Engineered wood products, like flooring, often come with tongue-and-groove systems or click-lock mechanisms, making them easier and faster to install compared to traditional hardwood. This reduces labor costs and installation time.

Compatibility with Underfloor Heating

Unlike solid wood, it is compatible with underfloor heating systems, making it an excellent choice for modern homes where warmth and comfort are a priority.

High Resistance to Warping and Cracking

The layered construction of this wood makes it highly resistant to warping, cracking, and splitting. This makes it more suitable for areas with fluctuating temperatures and moisture levels.

Engineered Wood vs. Solid Wood: A Detailed Comparison

| Feature | Engineered Wood | Solid Wood |

|---|---|---|

| Stability | Highly stable, less prone to warping | Prone to expansion and contraction |

| Cost | More affordable | More expensive |

| Installation | Easy to install | Requires professional installation |

| Eco-Friendliness | Uses wood efficiently | Uses more raw wood |

| Aesthetic Options | Wide range of finishes and textures | Natural wood grains and patterns |

| Maintenance | Easy to maintain | Requires regular refinishing |

Common Types Products

Here are some of the most popular types:

1. Plywood

Made from thin layers of wood veneers glued together, plywood is a versatile and widely used material in construction and furniture making. It’s known for its strength and stability.

2. Medium-Density Fiberboard (MDF)

MDF is made from wood fibers bonded with resin and wax, resulting in a dense, smooth material that’s easy to cut and shape. It’s commonly used in cabinetry, furniture, and decorative moldings.

3. Oriented Strand Board (OSB)

OSB is made from layers of wood strands arranged in specific orientations and bonded together. It’s commonly used for sheathing, flooring, and roofing due to its strength and durability.

4. Laminated Veneer Lumber (LVL)

LVL is composed of thin wood veneers bonded together under heat and pressure. It’s typically used in structural applications such as beams and headers due to its high strength.

5. Cross-Laminated Timber (CLT)

CLT is a large, solid wood panel made by gluing layers of wood together at right angles. It’s commonly used in building construction and is praised for its strength and sustainability.

Applications in Construction and Design

Engineered wood is incredibly versatile, making it suitable for a variety of applications, including:

- Flooring: Engineered wood flooring is a popular choice because of its durability, stability, and easy installation.

- Furniture: Many modern furniture pieces are made using engineered wood, offering both style and affordability.

- Wall Panels: Engineered wood panels can add warmth and texture to walls, creating a unique interior design feature.

- Structural Elements: Products like LVL and CLT are used in beams, columns, and even entire building structures, showcasing the strength of engineered wood.

Tips for Choosing Quality Engineered Wood

When selecting engineered wood for your project, consider the following tips:

- Check the Thickness: Thicker veneers and layers indicate a more durable and stable product.

- Inspect the Core Material: Ensure the core is made from high-quality wood layers for maximum stability.

- Consider the Finish: Choose a finish that complements your design and offers the durability you need.

- Opt for Reputable Brands: Stick to well-known manufacturers who prioritize quality and sustainability.

Challenges and Considerations

While has many advantages, it’s essential to be aware of potential challenges:

- Moisture Sensitivity: Although engineered wood is more moisture-resistant than solid wood, it can still be damaged by excessive water exposure.

- Lower Resale Value: In some cases, homes with this wood flooring might have a slightly lower resale value compared to those with solid hardwood.

- Potential Emissions: Some engineered wood products use adhesives that emit volatile organic compounds (VOCs). Look for low-VOC or eco-friendly options to minimize this issue.

Conclusion

Engineered wood is a versatile, cost-effective, and sustainable alternative to traditional solid wood, offering a wide range of applications in modern construction and design. With its stability, strength, and design flexibility, it’s no surprise that engineered wood is becoming a go-to choice for homeowners, builders, and designers alike.

You can read more articles by visiting our blog here.

_0_1200.jpg)