When it comes to selecting plywood for your construction or DIY project, understanding the different grades of plywood is crucial. Each grade signifies the quality and appearance of the plywood, which directly impacts its suitability for various applications. This comprehensive guide will help you navigate through the different grades, ensuring that you choose the best option for your project.

1. What Are Plywood Grades?

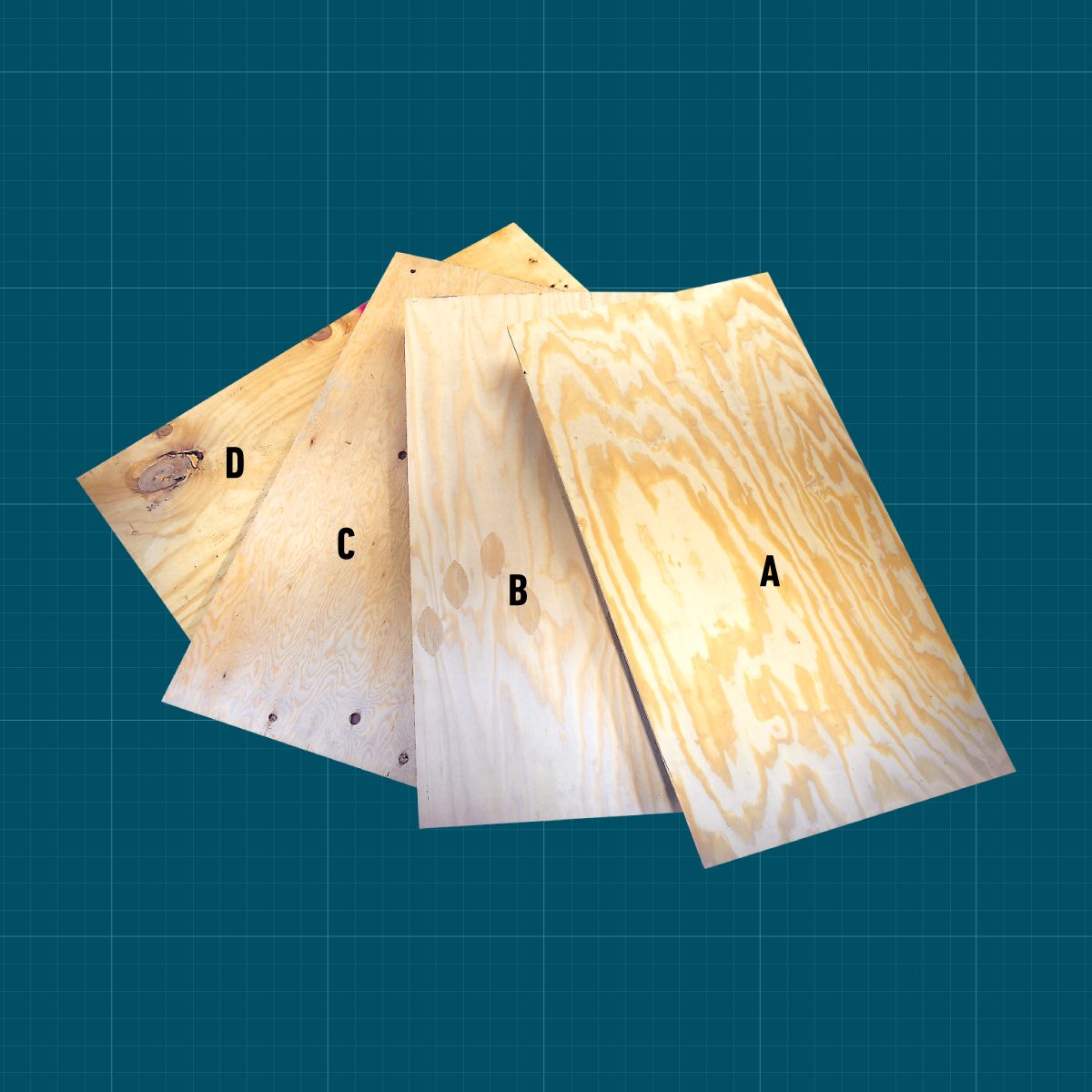

Plywood grades are classifications that indicate the quality of the wood, the smoothness of its surface, and the number of imperfections it has. These grades are typically assigned by the American Plywood Association (APA) and are represented by letters such as A, B, C, and D, with A being the highest quality and D the lowest.

2. Understanding the Different Grades

- Grade A:

- Quality: This is the highest quality plywood, featuring a smooth and sanded surface with minimal imperfections.

- Best For: Ideal for projects where appearance matters, such as cabinetry, furniture, and other visible surfaces.

- Features: Grade A may have very few, if any, visible knots or patches, making it perfect for staining or painting.

- Grade B:

- Quality: Slightly lower quality than Grade A but still offers a relatively smooth surface.

- Best For: Suitable for interior projects where some minor surface imperfections are acceptable, such as shelving or paneling.

- Features: Grade B may have small knots and repaired splits, but these are generally minimal and can be easily concealed.

- Grade C:

- Quality: Features more noticeable knots and surface defects compared to A and B grades.

- Best For: Often used in construction projects where the plywood will not be visible, such as subflooring or roofing.

- Features: Knots in Grade C are typically up to 1.5 inches in diameter, and the surface may have visible patches and splits.

- Grade D:

- Quality: The lowest grade with the most imperfections, including large knots and cracks.

- Best For: Primarily used for structural purposes where appearance is not a concern, like in wall sheathing or as a backing material.

- Features: Grade D may have open knots and other defects that are not repaired, making it unsuitable for finished surfaces.

3. Combination Grades

Plywood sheets often come with two grades, such as A-B, B-C, or C-D. The first letter represents the quality of the face veneer, while the second letter indicates the quality of the back veneer. For example:

- Grade A-B: High-quality face with a slightly lower quality back, perfect for projects where only one side will be visible.

- Grade B-C: Suitable for projects where one side will be exposed and requires a smooth finish, while the other side can have more imperfections.

4. Specialty Grades

- Exterior Plywood (X-Grade): Designed for outdoor use, exterior plywood is bonded with waterproof adhesive, making it resistant to moisture and decay. This is ideal for outdoor furniture, sheds, and other exterior applications.

- Marine Plywood: Known for its superior water resistance, marine plywood is used in environments where the wood is exposed to moisture regularly, such as in boat building or coastal construction projects. It is made with the highest quality veneers and waterproof glue, ensuring long-lasting durability.

- Sanded and Unsanded Plywood: Sanded plywood has a smooth, ready-to-finish surface, while unsanded is rougher and is often used in structural applications where surface smoothness is not required.

5. Choosing the Right Grade for Your Project

- For Visible Finishes: Choose A or B grade for projects like cabinetry, furniture, and interior walls, where appearance is critical.

- For Structural Applications: C and D grade are better suited for hidden or structural uses, such as subfloors, roof decking, or wall sheathing.

- For Outdoor Projects: Opt for exterior or marine grade to ensure your project withstands exposure to the elements.

Conclusion

Selecting the right plywood grade is essential for the success of your project. Whether you need a smooth, high-quality finish for visible surfaces or a sturdy, cost-effective material for structural support, understanding grades will help you make the best choice. By considering the specific requirements of your project, you can choose the grade that offers the perfect balance of quality, durability, and affordability.

Beside that, we have other guide to choose Melamine Plywood for furniture and interior Here.

See more guide or other topics Here.