Welcome to our exploration of sustainable practices in the Vietnam wood industry, focusing on the significance of FSC and PEFC certification. In this guide, we delve into how FSC and PEFC certifications play a crucial role in promoting sustainable forestry practices, meeting market demands, and enhancing the competitiveness of businesses in Vietnam’s wood industry. Join us as we uncover the importance and benefits of these certifications for both businesses and consumers alike.

Introduction

I. Overview of the Vietnam wood industry

Vietnam has emerged as a prominent global exporter of wood and wood products, securing its position as the fifth-largest wood exporter globally, second in Asia, and first in Southeast Asia on the international stage.

Despite Vietnam’s status as a top exporter of wood and wood products, its wood furniture export turnover represents merely 7% of the global market share. Considering the substantial scale of the world’s furniture trade market, valued at approximately USD 405 billion annually, and the import demand for wood and wood products reaching about USD 230 billion, there remains significant potential for growth in the wood processing industry. This is particularly true for furniture, a key commodity in Vietnam’s export portfolio.

In 2023, the export value of wood and wood products from Vietnam reached USD 13.5 billion, lower than the yearly target of 17 billion USD. Nonetheless, this decrease fell short of businesses’ expectations, particularly down 15.5 percent year-on-year.

II. Importance of sustainable practices

- Preservation of Forest Ecosystems: Ensuring the preservation of forest ecosystems is a paramount concern within the wood manufacturing industry. Sustainable wood production practices play a crucial role in safeguarding forest reserves for future generations and maintaining the delicate ecological balance.

- Minimizing Carbon Footprint: Wood serves as a significant carbon sink, and adopting sustainable wood production methods is instrumental in lessening the industry’s carbon footprint. Implementing sustainable approaches like reforestation, embracing renewable energy sources, and curbing waste can effectively mitigate the impacts of climate change.

- Economic Advantages: Embracing sustainable wood production can yield positive outcomes for the industry. Through the adoption of sustainable practices, new avenues for business expansion can be unlocked, leading to the creation of fresh revenue streams and enhanced market competitiveness.

- Social Accountability: Sustainable wood production encompasses a holistic approach that extends to the industry’s social implications. This entails upholding the rights of forest-dependent communities and ensuring that the industry’s operations do not detrimentally affect their livelihoods.

- Adhering to Regulations: The wood manufacturing industry is subject to various regulations and certifications. By embracing secure and sustainable practices, companies can guarantee compliance with these standards, thus averting the adverse repercussions of non-compliance.

- Consumer Preferences: There’s a growing consumer consciousness regarding the environmental footprint of their purchases. Companies integrating sustainable wood production methods stand to benefit from this trend by providing products aligned with consumer preferences for sustainability and eco-friendliness.

- Long-Term Sustainability: Sustainable wood production safeguards the industry’s long-term viability. Through the adoption of sustainable practices, companies can secure a dependable and sustainable supply of raw materials, which is crucial for the industry’s ongoing growth and advancement.

Historical Context

I. Evolution of the wood industry

Despite experiencing difficulties after being heavily affected by the pandemic, Vietnam’s exports of timber and non-timber forest products in 2021 were predicted to reach 15.6 billion USD, up by 18 percent compared to 2020. where the exports of wood and products reached 14.5 billion USD, up by 17.2 percent compared to 2020.

Vietnam’s timber and forest products are exported to over 140 countries and territories, of which the main markets are the US, Japan, China, the EU, and South Korea, with a total export value estimated at 13.98 billion USD, accounting for 89.5 percent of the country’s export value of forest products.

II. Past environmental impacts

- Deforestation: As the wood industry expanded, forests were cleared at an alarming rate. This led to the loss of precious trees and wildlife habitats, causing a decline in biodiversity.

- Soil Erosion: With trees removed, the soil became vulnerable to erosion by wind and rain. This erosion harmed the land, making it less fertile for agriculture.

- Habitat Destruction: Many plant and animal species lost their homes due to deforestation. This disrupted the natural balance of ecosystems, impacting the survival of various species.

- Water Pollution: Some wood processing plants didn’t handle waste properly, leading to pollution of water sources. This pollution harmed aquatic life and made water unsafe for drinking and farming.

III. Current Challenges

The wood sector in Vietnam encountered significant hurdles during 2023. Reduced consumer demand in critical export destinations such as the US and the EU led to a notable decline in orders. Consequently, many enterprises had to reduce their production capacity, and in some cases, suspend operations entirely.

As reported by the Vietnam Timber and Forest Products Association (Viforest), projections indicate that Vietnam’s exports of wood and wooden furniture are expected to reach approximately 13.5 billion USD in 2023, marking a decrease of 15.5% compared to the previous year.

At present, there are few indications of a rapid resurgence in purchasing power for wood products within global markets, particularly in the US market, which has historically accounted for over 50% of Vietnam’s exported wood products.

Apart from market challenges, the timber industry is grappling with significant issues concerning the legality and sustainability of its products. The EU’s anti-deforestation regulation, implemented in June 2023, imposes stringent criteria for legality, zero deforestation, and minimal carbon emissions.

Sustainable Practices

I. Forest Stewardship Council (FSC)

1. About FSC and FSC Certification

The Forest Stewardship Council (FSC) is an international, non-governmental organisation dedicated to promoting responsible management of the world’s forests. Since its foundation in 1994, FSC has grown to become the world’s most respected and widespread forest certification system.

FSC’s pioneering certification system, which now covers more than 200 million hectares of forest, enables businesses and consumers to choose wood, paper, and other forest products made with materials that support responsible forestry.

FSC certification, or Forest Stewardship Council certification, is a globally recognized standard for sustainable forestry practices. This certification ensures that wood and wood products come from responsibly managed forests that meet strict environmental, social, and economic standards. By choosing FSC-certified products, consumers contribute to the preservation of forests, the protection of biodiversity, and support for local communities. Moreover, businesses that obtain FSC certification enhance their credibility, gain access to eco-conscious markets, and demonstrate their commitment to sustainability. Explore the advantages of FSC certification and join the movement towards a more sustainable future.

2. Types of FSC certification

- FMC (Forest Management Certificate): As a forest protection certification, it is awarded to forest areas of a country that have met standards related to environmental, social, and economic aspects.

- CoC (Chain of Custidy Certificate): It is a type of certification for product chains. This is extremely useful because it helps transparently communicate information to consumers and limits the practice of some manufacturers (mainly in China) attaching FSC certification without FSC permission. This is a process chain from the early stages to the transfer to consumers using the product. FSC certification helps confirm products made from forest wood with clear origins, meeting all the criteria of the FSC organization.

- FSC-CoC/CW (FSC-Chain of Custody/Control Wood) Certificate: Product Journey Certification, evaluating controlled wood origins.

II. Programme for the Endorsement of Forest Certification (PEFC)

1. About PEFC and PEFC Certification

Currently, nationwide, there are only over 280,000 hectares of forest certified with the FSC, a very modest figure compared to the total area of the country’s production forests. Therefore, the PEFC forest certification is being strongly promoted for application to increase the area of certified forests to meet market demand and enhance the value of the forestry and wood processing industry.

The PEFC (Programme for the Endorsement of Forest Certification) is the world’s largest sustainable forest management certification system, covering an area of over 308 million hectares, accounting for 60% of the certified forest area worldwide.

The PEFC is a non-profit organization established in 1999 in Europe (in France), with the goal of promoting and protecting forests at national, regional, and global levels through collaboration and support for member countries in building and operating national forest certification systems. Vietnam is the 50th member out of a total of 51 member countries of PEFC.

PEFC works throughout the supply chain to promote best practices in forest management and ensure that wood and forest products are produced and comply with the highest ecological, social, and ethical standards. Through the eco-label, customers and consumers can identify forest products that are sustainably managed.

2. Types of PEFC

- PEFC-FM (Forest Management Certification): The PEFC-FM certification is intended for organizations and units involved in forest planting and harvesting.

- PEFC-CoC (Chain of Custody Certification): The entire supply chain, from forest wood sources to end consumers, must be monitored and documented to prove its origin. This evidence is referred to as the PEFC Chain of Custody (CoC) certification. The PEFC-CoC certification is intended for units processing forest products. It certifies the management system for units involved in the production, processing, and trading of forest products.

Economic Considerations

I. Market demand for sustainable products

1. Of FSC:

The market demand for sustainable products certified by FSC (Forest Stewardship Council) in Vietnam is steadily growing. With an increasing awareness of environmental issues among consumers, there is a growing preference for products that are sourced from responsibly managed forests and adhere to strict environmental, social, and economic standards.

This trend is driven not only by local consumers but also by international buyers who prioritize sustainability in their purchasing decisions. As a result, businesses in Vietnam that offer FSC-certified products have a competitive advantage in both domestic and international markets, catering to the rising demand for sustainable and eco-friendly options.

2. Of PEFC:

The market demand for sustainable products certified by PEFC (Programme for the Endorsement of Forest Certification) in Vietnam is also on the rise. Similar to the demand for FSC-certified products, consumers in Vietnam are increasingly conscious of environmental sustainability and are seeking products that come from responsibly managed forests.

PEFC certification ensures that wood and wood products meet stringent standards for sustainable forest management, making them attractive to environmentally-conscious consumers. Additionally, as Vietnam continues to expand its export market for wood products, international buyers are increasingly seeking PEFC-certified products to meet their own sustainability goals.

This growing demand for PEFC-certified products presents significant opportunities for businesses in Vietnam to capitalize on the trend towards sustainability and expand their market reach both domestically and internationally.

II. Benefit analysis of sustainable practices

1. FSC

- Economic Benefits:

FSC helps conserve forest resources, enhance economic value, and increase the value of products and items. According to FSC statistics, certified products have a higher economic value of 20–30% compared to similar products. This helps reduce waste from the improper use of forest resources.

- Brand Benefits:

When input materials are FSC certified, it elevates the brand of the product. Businesses can promote their products by using FSC certification in their communications.

- Environmental Benefits:

FSC has strict principles because it helps protect the environment and natural ecosystems in a special way, encompassing not only forest resources but also air and water. Activities calling for the non-use of atrazine in herbicides are an example, as it affects both air and water sources.

- Social Benefits:

The Forest Stewardship Council (FSC) demonstrates this organization’s responsibility to society as an organization responsible for human life.

2. PEFC

PEFC certification is a significant proof of sustainable forest management and provides businesses with outstanding advantages:

- The use of the PEFC label signifies forest products produced from materials sourced from a region with sustainable and legal management.

- Easier access to international markets for wood products. Some countries and regions worldwide are implementing laws to reject illegally produced wood products, such as Europe, Australia, the United States, Japan, China, etc..

- Establishing an effective wood product monitoring process to minimize risks related to product quality issues and enhance competitiveness.

- Meeting the requirements of customers and business partners.

- Increasing revenue from selling PEFC-certified products.

- Sending a strong message about credibility and social responsibility to customers and business partners.

Companies in Vietnam that have sustainable certification

I. Companies leading in sustainable practices

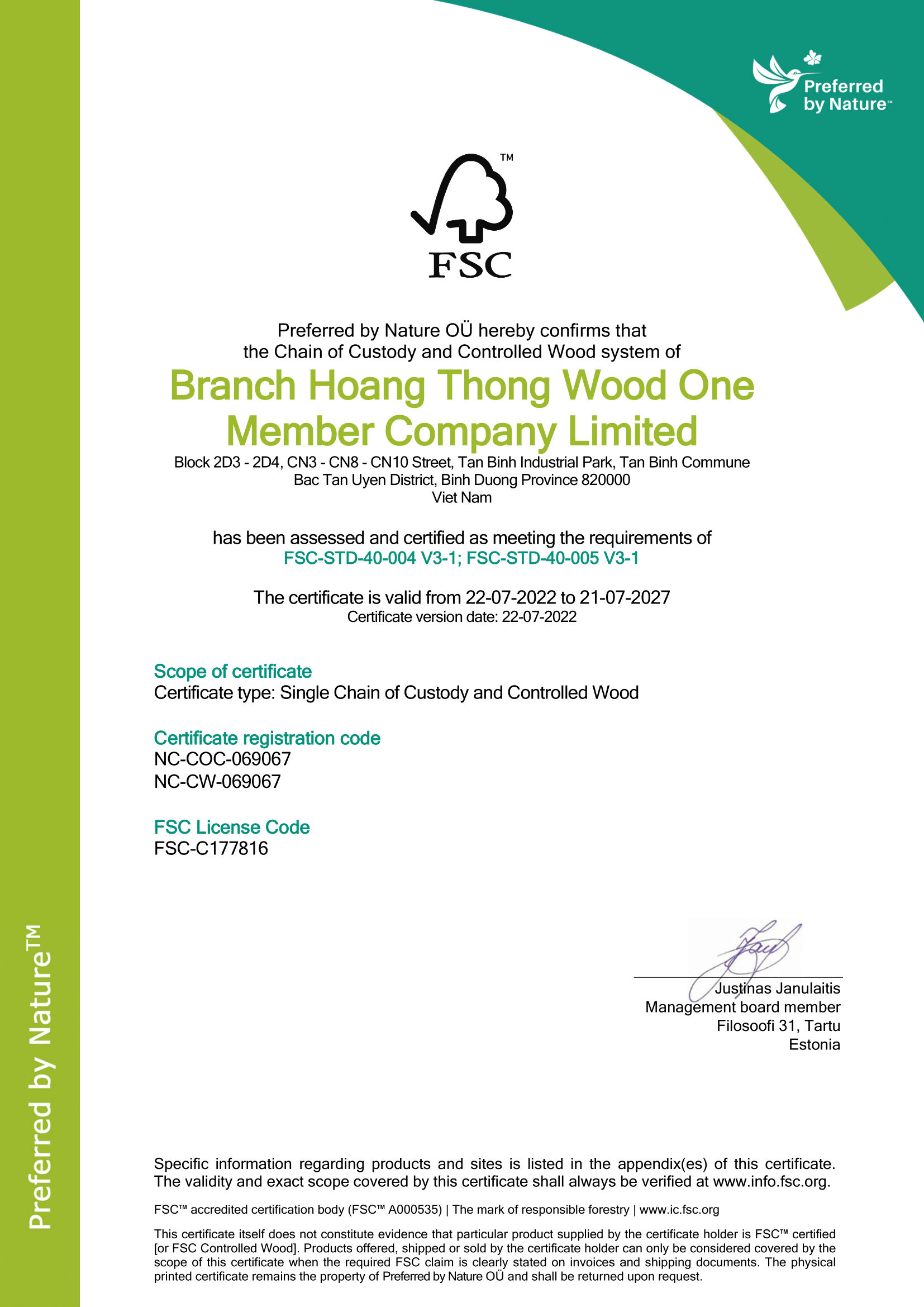

Hoang Thong is a leading company in the field of exporting rubber wood and acacia wood products from Vietnam. Hoang Thong specializes in providing the best solutions for customers through a range of high-quality products at competitive and reasonable prices, coupled with excellent customer service.

Company Site: https://hoangthongwood.com/

Year Established: 2014

Product and Service: Rubberwood Laminated Board, Indoor Furniture, UV-Finished Butcher Block

Factory Square: 130,000 m2

Production Capacity: 15,000 m3/month

Workforce: 2,700 people

Certifications: FSC-CoC, Sedex SMETA, QSA, C-TPAT, GMP Quality, Carb P2 and EPA

Nhat Huy Group was established in 2004 as an exporter of calcium carbonate powder. Nhat Huy has developed as a manufacturer from Vietnam with excellent results in international manufacturers, focusing on calcium carbonate powder, plastic support materials, natural stone, and quartz stone.

Company Site: https://nhathuywoods.com.vn/

Year Established: 2004

Product and Service: Acacia Live Edge Panel, Acacia Solid Panel, Acacia Finger Joint Panel, Butcher Block

Factory Square: 50,000 m2

Production Capacity: 2,000 m3/month

Certifications: FSC-CoC

Founded in 2014, BWG Mai Chau Joint Stock Company resulted from the merger and acquisition of a business with 12 years of expertise in industrial bamboo and wood production in Mai Chau district, Hoa Binh province, Vietnam. Commencing in 2015, BWG has made substantial investments in establishing the largest and most advanced industrial bamboo manufacturing facility in Vietnam, boasting an annual capacity of 120,000 m3 and meeting international standards. Spanning an extensive 6-hectare area at the Chieng Chau Industrial Zone, Mai Chau District, Hoa Binh Province, the factory stands as a testament to BWG’s commitment to excellence in the industry.

Company Site: https://bwg.vn/

Year Established: 2014

Product and Service: Furniture, Panel, Beams, Lumber, Outdoor, Kitchenware, Accessories

Factory Square: 6 Hectare of factory

Product Capability: 120,000 m3 per year

Workforce: 250 Employees

Certification: ISO 9001, BSCI, FSC, FDA, LFGB, FCMS, TUV Rheinland, BUREAU VERITAS, AICA, SA, Dynea

II. B2B platforms to find FSC manufacturer in Vietnam

Vietnamwood Marketplace (https://vietnamwood.com.vn/marketplace/)

Vietnam-B2B (https://vietnam-b2b.com/)

ExportHub (https://www.exporthub.com/)

Fordaq (https://www.fordaq.com/)

Tradekey (https://www.tradekey.com/)

Discover how FSC and PEFC certifications are revolutionizing sustainability in Vietnam’s wood industry. Dive into the transformative impact of these certifications, driving forward eco-friendly practices and shaping the future of wood production in 2024.

Read more blogs about the wood industry: