In this article, VietnamWood will introduce the fundamental concepts of wood veneer quality. This is because many people often confuse different terms related to various types of wood-based materials, such as MDF, MFC, veneer, plywood, etc. This confusion can lead to mistakes when choosing wood for production or DIY woodworking projects. So, let’s explore this type of wood together with VietnamWood.

Read more: What is Knotty Oak Veneer and Its 6 Best Applications

Eco Veneer – One of the Best Sustainable Alternative Material

What is wood veneer?

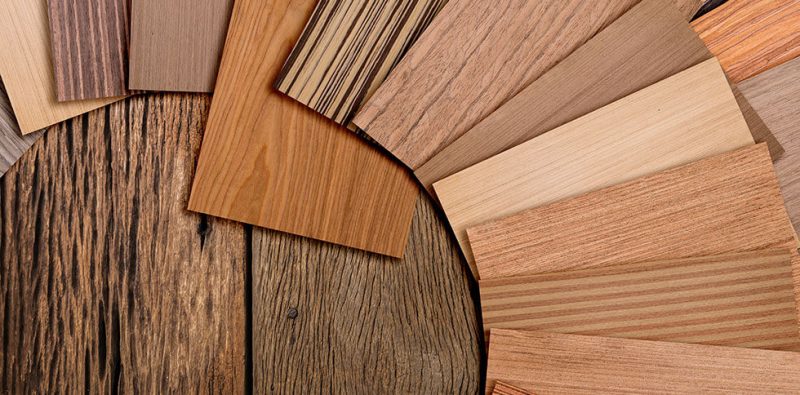

Wood veneer is a thin layer of real wood, typically ranging from 0.6 to 6 millimeters in thickness, that is peeled or sliced from a log or timber. It is used to cover the surface of various wood-based products, such as plywood, particleboard, or medium-density fiberboard (MDF), to enhance their appearance and mimic the look of solid wood.

Wood veneer is prized for its natural beauty, grain patterns, and variety of wood species available, which include oak, maple, cherry, walnut, and many others. It is often used in furniture making, cabinetry, interior and architectural design, and woodworking projects where a high-quality wood finish is desired.

Wood veneer quality assessment standards

Assessing the quality of wood veneer involves evaluating several factors to ensure it meets the desired standards for appearance and performance. While specific standards may vary depending on the application and industry, here are some common criteria used for assessing wood veneer quality:

- Grain pattern

The grain pattern should be consistent and visually appealing. It’s important to check for any irregularities, such as knots, splits, or grain tear-out, that may affect the overall appearance.

- Color and consistency

The color of the veneer should be uniform across the entire sheet or panel. Any significant variations in color may require sorting or grading to ensure a cohesive look in the final product.

- Matching

When using multiple sheets of veneer in a project, they should be carefully matched to create a harmonious appearance. This includes bookmatching (mirroring veneer sheets), slip matching, and sequence matching to achieve the desired aesthetic.

- Cutting method

Different cutting methods, such as plain-sliced, quarter-sliced, rift-cut, or rotary-cut, result in varying grain patterns. The choice of cutting method should align with the project’s design and aesthetic goals.

- Veneer thickness

The thickness of the veneer should meet the specified requirements and should be consistent across the sheet. Thin or uneven veneer can affect the veneering process and the final product’s durability.

- Flatness

Veneer sheets should be flat and free from warping, buckling, or any other deformities that could make them difficult to work with.

- Backing material

In some cases, veneer may be backed with a substrate material (e.g., paper, fleece, or wood). The quality and adhesion of the backing material should meet industry standards to ensure the veneer’s stability.

- Adhesive quality

The adhesive used to bond the veneer to the substrate should be durable, heat-resistant, and moisture-resistant. It should also adhere securely to prevent delamination.

- Finish and surface quality

The surface should be smooth, free from scratches, blemishes, or finishing defects. The finish applied, such as clear coat or stain, should be even and consistent.

- Grade and certification

Many wood veneers are graded based on quality standards established by industry organizations. Check for any applicable certifications or grading information to ensure compliance with quality standards.

- Environmental considerations

Assess whether the wood veneer meets sustainability and environmental standards, such as FSC (Forest Stewardship Council) certification, which ensures responsible sourcing of wood.

- Testing

In some cases, wood veneer may undergo testing for specific properties, such as fire resistance, moisture resistance, or durability, depending on the intended application.

Wood veneer quality vs. Solid wood furniture

Wood veneer and solid wood are two different materials that are widely used in furniture design and production, each with its own set of characteristics and features. Here are some criteria used to compare wood veneer quality and solid wood furniture

| Wood veneer quality | Solid wood furniture | |

| Appearance and aesthetics | High-quality wood veneer can replicate the look of solid wood with beautiful grain patterns. It often offers a more consistent appearance than solid wood, as it is carefully selected and matched. | Solid wood furniture showcases the natural beauty of wood, including unique grain patterns and variations in color. It can have a rich, organic look that many people find appealing. |

| Cost | Veneered furniture is generally more cost-effective than solid wood furniture. It allows you to achieve the look of expensive hardwoods at a lower price. | Solid wood furniture is often more expensive due to the use of full wood boards or pieces. |

| Durability and strength | The durability of veneer furniture depends on the quality of the veneer and the underlying substrate (e.g., plywood or MDF). High-quality veneer furniture can be quite durable. | Solid wood furniture is known for its strength and longevity. It can withstand wear and tear, making it a long-term investment. |

| Stability | Veneered furniture may be less prone to warping or splitting compared to solid wood because it is less affected by changes in humidity. | Solid wood can be more susceptible to environmental changes, leading to expansion or contraction, which may affect its stability. |

| Environmental impact | High-quality veneer often makes efficient use of wood resources, reducing the demand for solid wood. Look for veneer products with sustainable sourcing practices. | Solid wood furniture may use larger amounts of timber, potentially impacting deforestation and resource consumption. Sustainable wood sourcing is essential for environmentally responsible choices. |

| Repair and refinishing | Veneered furniture can be more challenging to repair or refinish because it involves working with thin layers. However, minor repairs and touch-ups are possible. | Solid wood furniture is easier to repair and refinish, as it can be sanded, stained, or refinished multiple times over its lifespan. |

| Weight | Veneered furniture is often lighter than solid wood furniture, which can be advantageous for portability and ease of movement. | Solid wood furniture tends to be heavier due to its solid composition. |

The choice between wood veneer quality and solid wood furniture depends on your specific preferences, budget, and intended use. High-quality veneer can offer an excellent balance of aesthetics and cost savings, while solid wood provides unmatched durability and a timeless appeal.

Instructions on how to choose good quality wood veneer

Choosing high-quality wood veneer products requires time and effort, and there are specific factors that buyers need to consider to find wood veneer quality for creating excellent products for their customers. Below are some guidelines that can assist you in finding wood veneer quality that meets your needs:

1. Select wood species

Choose the type of wood that suits the needs of your customers or is appropriate for the products your business is manufacturing. Different wood species have unique characteristics such as hardness, durability, distinct grain patterns, and varying colors. Therefore, carefully consider selecting the wood type as one of the first things to prioritize.

2. Thickness

Determine the thickness you want for the type of wood veneer you are seeking. Wood veneer typically ranges from 0.3mm to 0.6mm in thickness and should not exceed 3mm. Choosing the precise thickness will ensure that your finished product meets your exact specifications.

3. Grade

Wood veneer is categorized into grades to reflect the quality of the wood. Wood veneer with a grade of A or AA is typically of the highest quality. This is an important point to consider when evaluate wood veneer quality, as higher-grade veneers are less likely to have imperfections and defects, ensuring a better overall appearance and performance in your projects.

4. Visual inspection

Inspect the veneer sheets or rolls visually. Look for the following:

- Uniform color and grain pattern

- Minimal defects like knots, splits, or cracks

- Consistency in thickness

5. Sample and sample matching

Request samples from the supplier to evaluate the actual appearance, color, and grain pattern. Ensure that the samples match the quality of the bulk veneer you plan to purchase

6. Sustainability

If sustainability is a concern, inquire about the veneer’s sourcing and look for certifications that indicate responsible forest management and assure the wood veneer quality

7. Budget

Determine your budget for the veneer and select the wood veneer quality that aligns with your budget constraints.

VietnamWood – Providing good quality wood veneer at reasonable prices

With the advantages mentioned above, it’s evident that the potential of wood veneer will continue to grow in popularity in the future. For businesses, this is an opportunity for investment and production, and for individual customers, DIY home furniture projects using high quality wood veneer have become a trend in recent years.

VietnamWood has a network of over 1000 wood manufacturing businesses and wood product suppliers within the territory. If you’re interested in learning more about pricing or seeing good quality wood veneer up close, please don’t hesitate to contact us through the messaging section on our website.

VietnamWood is more than happy to address any inquiries you may have regarding these products.

From the article, it’s evident that wood veneer quality is a matter of great concern for many businesses, especially those in need of purchasing and sourcing wood veneer as a material for their production. It is our hope that this VietnamWood article has provided the necessary information regarding wood veneer quality.